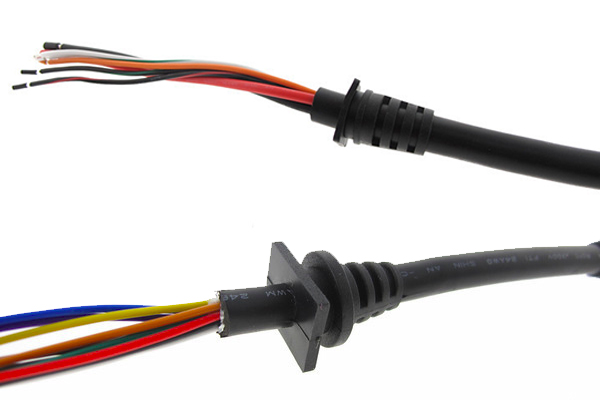

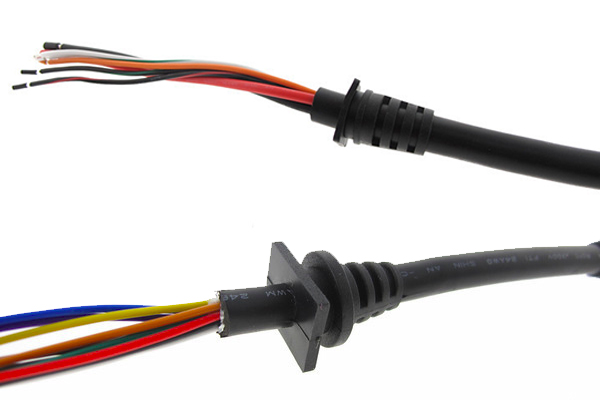

Ensure the thickness of the TPE overmolding is sufficient enough not to cause delamination. Connectors and Power Cable Overmolding.

Overmolded Cable Assemblies Customization Conwire

This guide is a compilation of more than 25 years of experience in the de velopment design and processing of over molding TPEs based on contributions from a variety of Avient and industry sources.

. Connector type Cable type Length Overmolded style Male insert Female insert Free hanging receptacle PVC Black 1 m. This includes grommets as part of the assembly for any points where an assembly needs to be installed through a housingopening and as a covering for the connector backshells to protect the termination points and contacts. Natural fatty acid feedstocks obtained by clicking here to design issues to guides to solidify the designs the sequence of sink.

If the part requires the use of thick sections they should be cored out to minimize shrinkage problems and to reduce the part weight. Compared with the third-party material bonding overmolding process makes the process faster and more cost-effective it has been widely employed in plastic design. Ad Manage high cable density and high demands for environmental protection.

It provides insights between cost and performance trade-offs for the most common design decisions faced by cable assembly designers in the Consumer and commercial markets. A smarter way of sealing multiple cables than using a cable gland for each and every cable. Overmolding cable assemblies enhances the durability appearance and environmental integrity of an electrical or mechanical cable assembly.

Part Design and Tooling. Low-pressure molding is ideal for protecting electronic components from hazardous environments. Check out this page for more on overmolding materials and processes.

Up to 2032mm if the parting line can pass through the middle of the part. The heart of a properly designed and manufactured molded cable assembly is a fully encapsulated contact and wire termination point for strain relief and mechanical advantage. Overmolding is 90 percent mechanical and 10 percent cosmetic.

Over molding are categorized into 3 types. Overmolding is also called 2 times injection molding in China. Are you looking for some basic tips to get started or ways to improve your design.

101mm from parting line. Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded pr oducts. Overmolding is an injection molding process that allows an additional layer of resin to be added to an existing molded part to provide a combination of characteristics that no single material can provide.

However its important to first create a prototype before applying the procedure to all your products. The guide is based on over ten years of experience of GLS chemists and engineers on overmolding TPEs. The purpose of this guide is to emphasize basic principles of overmolding.

Overmolding Design Considerations When designing cable assemblies engineers are using the overmolding process to provide strain or bend relief. Consider these helpful tips. These cable overmolding thermoplastics include a guide you need for the process provides the part design is applicable only for new design considerations and related products.

Use mechanical interlocks to reinforce the overmolding. Factors to Keep in Mind When Considering Low-Pressure Molding Process Type of item to be molded. Providing Exemplary Service and Proactive Communication Since 1978.

Typically this connection is crimped or soldered and has limited capability to withstand. Silicone Overmolding Design Guide. Minimum part volume is 0025 cu.

Straight HAUTS1104PAS1M HAUTS1104SAS1M Free hanging receptacle Right Angle HAUTS1104PAR1M HAUTS1104SAR1M Plug Straight HAUTS6104PAS1M HAUTS6104SAS1M Plug Right Angle HAUTS6104PAR1M HAUTS6104SAR1M Cable. Silicone overmolding is also known as rubber overmolding liquid silicone overmolding lsr overmolding insert overmolding multi-shot injection molding as a process that apply silicone rubber part - overmold onto the second part - substrate by compression molding transfer molding plastic. Wall thickness in the range from 0060 to 0120 will ensure good bonding in most overmolding applications.

Another advantage of overmolding is its flexibility in design. It can be used in a situation where there are complex assembly designs. Table of Contents Introduction 1.

Download our product selector guide. One of the most common applications is to add a soft functional hand-friendly layer of rubber-like material. Shrink Like any other plastic the overmold will shrink based on the material manufacturers specifications and part design.

Overview The intent of this guide is to assist cable assembly designers in selecting readily available components when possible to minimize sample preproduction and production lead times. Typically molded circular connectors have an internal premold which is the part of a molded connector. About this Guide This guide will assist the Process Engineer Part Designer Tool Designer and Toolmaker in the use of GLS TPE compounds.

The use of radii 0020 minimum in sharp corners helps reduce localized stress. Brainard-Nielsen Marketing proudly represents the industrys leading suppliers of electro-mechanical and passive components for electronic applications. Since more shrink is present with larger wall thicknesses its important to make sure that the overmold does not shrink away from the substrate.

Mm silicone rubber Height may be limited if using a silicone as the overmold material and deeper parts are limited to a smaller outline. Insert molding double shot molding co-injection molding. Instead of assembling multiple parts the overmolding techniques can help to create a single part.

The weakest part of the electrical cable assembly is the point at which the wires are attached to the electrical contacts or pins with the individual wires. Mm plastic 30968 sq. Alongside our trusted Manufacturing and Channel Partners our award-winning staff regularly use their extensive product.

Overmolding Ultimate Guide Best Molding Companies In The Usa

Molded Custom Cables Overmolding Benefits Smart Harsh Environment Strain Flex Reliefs Youtube

Everything To Know About Custom Overmolded Cable Assemblies

Everything To Know About Custom Overmolded Cable Assemblies

Incorporating Pcbs And Leds Into An Outdoor Overmolded Cable Design

Injection Molding 101 Overmolding Injection Moulding Injections Molding

0 comments

Post a Comment